Products

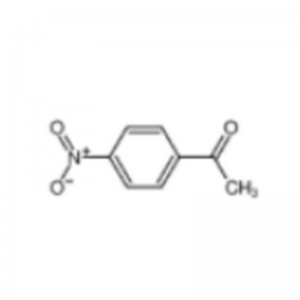

P-Nitroacetophenone

Product Info

CAS NO: 100-19-6

Purity: ≥99%

Formula: C8H7NO3

Formula Wt: 165.15

Chemical Name: 4-Nitroacetophenone;

4’-Nitroacetophenone; p-Nitroacetophenone

IUPAC Name: 1-(4-nitrophenyl)ethanone;

Ethanone, 1-(4-nitrophenyl)-

Melting Point: 75-78°C

Boiling Point: 202°C

Flash Point: 201-202°C

Appearance: Yellow prism or bright yellow powder

Shipping and Storage

Store Temp: Room Temperature

P-nitroacetophenone is an important intermediate in organic synthesis and is used as a raw material for the synthesis of chlortetracycline and chloramphenicol in medicine. The traditional method for the industrial production of p-nitroacetophenone is the oxidation of ethylbenzene. In addition to the main product p-nitroacetophenone, there are by-products such as p-nitrobenzoic acid in the reaction system. The production wastewater has the following characteristics: ① high concentration, strong acidity, dark color and high toxicity; ② the structure of the compound in the wastewater is quite stable and not easily biodegradable, so the general methods such as activated carbon adsorption, electrolysis and precipitation cannot achieve the desired effect. Resin adsorbent has strong adsorption and regeneration ability, and its physical and chemical properties are stable and can be used repeatedly.

Properties

Pure product is light yellow crystal or needle crystal. Melting point 80~82℃. Boiling point 202℃. Freely soluble in hot ethanol, ether and benzene, insoluble in water.

Preparation

Ethylbenzene is nitrated with mixed acid at 30~35℃ to get nitroethylbenzene. After distillation, p-nitroethylbenzene and the co-product o-nitroethylbenzene are obtained. In the presence of catalyst cobalt stearate, p-nitroethylbenzene is oxidized with air at 140-150℃ and 0.2MPa pressure to obtain p-nitroacetophenone. The reaction product was washed with water, neutralized, centrifuged and dehydrated, and dried to give the finished product.

p-Nitrobenzoyl chloride method.

Safety

Toxicity is not known. The production equipment should be airtight and the operator should wear protective gear.

Packed in iron drums or wooden drums lined with plastic bags. Store in a dry and ventilated place.